Part Two is here

Part Three here

Now to focus on the speaker chambers.

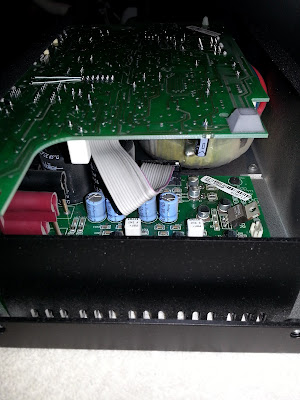

Another bit of online shopping snagged some self-adhesive sheets of sound deadening for £8 to help with damping the panels - I used these on all the speaker chamber surfaces that had room for them. I also used a set of 4x 40mm Polipod feet underneath to both raise the box up to allow airflow, and to try and stop energy going into the surface on which the box is going to stand - typically this will be a table and they're horrible when they start vibrating along with music. The Polipods were drilled and screwed to the underside.

The mid-bass drivers are fitted on the front and the rear with rubber sealing rings, the tweeters aren't. So the drivers were installed into the cabinet (pilot holes being drilled first for the screws), then sealed with clear silicon sealant from inside the cabinet. Speaker cables from the crossovers are soldered onto the drivers. The anti-vibration sheets were then cut to size and stuck onto the relevant panels. Cables were then p-clipped into position and sealant applied to where the cables enter the speaker chamber.

|

| Speaker chamber completed, damping panels in place. Note the hinged lid |

Playing some tunes from the FiiO portable FLAC player produced a fairly light, boomy kind of sound - pretty much as you might expect when just looking at the completed box. Another quick Google search reveals that most infinite baffle speakers use polyester as a filling material - just like many a low cost pillow, of which there were a few old ones lying around in the garage - good protective packing when moving stuff around in the boot of the car. One was opened up and the polyester filling teased out (wearing a breathing mask and rubber gloves for this) and each speaker chamber filled with half of the content of one pillow.

|

| FiiO X3 FLAC player used as a source during testing |

Well, this was not a small nor subtle change - more bass, more control, but still boxy. Another pillow was sacrificed and another improvement noted. A third pillow was pressed into service, and it took a bit of compressing to get this material into the chambers. But this was very successful - providing much deeper and more controlled bass, with much much less boxiness. So the less than scientific approach of trying different options gave a good final position.

|

| Each speaker chamber stuffed with the content of 1.5 polyester pillows |

A very pleasing result, and one that has a nod to its Linn heritage through the use of the "Krate" die-cut stickers (another £5) and the XL label as it's pretty big!

|

| Constructed from an ex-Austrian Army ammo box. Very solid pine and ply panels, heavy duty rope handles, robust hinges - you get the picture |

|

| Shiny volume knob is the only concession to any kind of quality look |

|

| Playing tunes on the dining table. It sounds better than it looks! Linn silver interconnects in use at this point. |